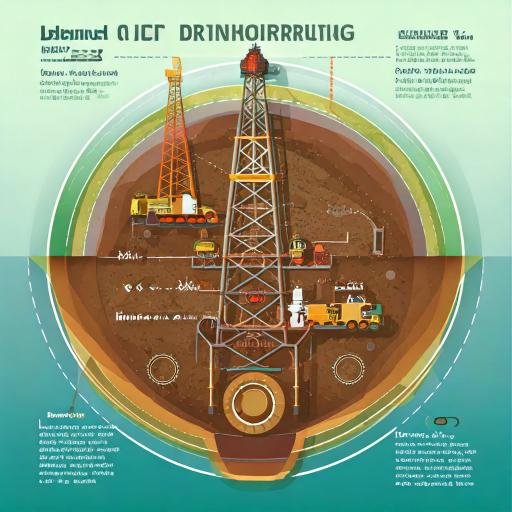

A Quick Look At Directional Drilling

Directional drilling is a crucial technology in modern engineering, especially in the fields of oil and gas extraction, geothermal energy production, and infrastructure development. Unlike traditional vertical drilling, directional drilling allows engineers to drill wells at specific angles or horizontal directions. This technology has opened up numerous possibilities in accessing resources, maximizing productivity, and reducing environmental impacts. In this article, we’ll explore what directional drilling is, how it works, its various applications, and why it’s become an indispensable tool in many industries.

What is Directional Drilling?

Directional drilling is a technique used to drill wells or holes at an angle, rather than straight down. By manipulating the drill path, engineers can precisely target specific underground zones, even reaching areas located beneath obstacles such as bodies of water or urban environments. This allows for greater control and flexibility in reaching resources located away from a well’s initial surface location.

Initially developed for oil and gas drilling, directional drilling has evolved significantly over the years and is now applied in several other industries, including geothermal energy production, construction, and environmental management. This technology has become a vital solution for accessing resources efficiently, maximizing yields, and minimizing the environmental footprint of drilling operations.

Types of Directional Drilling Techniques

Directional drilling encompasses several techniques, each designed to meet specific project requirements:

- Horizontal Drilling: This technique involves drilling at an angle close to 90 degrees, allowing for horizontal wellbore paths. Horizontal drilling is commonly used in oil and gas fields to access resources spread over a wide area, such as shale formations. It increases the exposure of the well to the resource, significantly enhancing production rates.

- Slant Drilling: In this method, the drill enters the ground at a slanting angle instead of vertical. Slant drilling is typically used in regions where vertical drilling is impossible due to environmental or structural limitations, such as in crowded urban areas or near water bodies.

- Extended Reach Drilling (ERD): ERD involves drilling wells with very long horizontal sections. This allows companies to reach distant resources without creating multiple drill sites. ERD is especially useful for offshore drilling projects where accessing far-flung reservoirs from a single platform can reduce costs and minimize environmental impact.

- Multilateral Drilling: In this technique, multiple branches (or laterals) are drilled from a single wellbore. Multilateral drilling is used to maximize the productivity of a single well by reaching multiple resource zones. This technique reduces the need for additional surface infrastructure and is a cost-effective way to enhance production.

- Directional Boring: Commonly used in construction and infrastructure development, directional boring (or horizontal directional drilling) allows for the installation of pipelines and utilities under obstacles like roads and rivers without disrupting the surface. This technique is widely used in telecommunications, water, and gas pipeline installations.

Each of these techniques has unique advantages and applications, making directional drilling adaptable to a wide range of engineering and industrial needs.

The Process of Directional Drilling

The directional drilling process begins with detailed planning, where engineers design the drill path to reach the target resource while considering geological conditions, safety, and environmental factors. Here are the basic steps involved:

- Pre-Drilling Survey and Planning: Engineers conduct geological surveys to understand the subsurface conditions and design a drill path that will effectively reach the target while minimizing risks. Advanced software and 3D modeling tools are often used in this stage to create accurate drilling plans.

- Drill Rig Setup: Once the drill path is defined, the drill rig is set up at the surface location. Specialized rigs with adjustable angles are often used for directional drilling to allow for precise control over the drill’s trajectory.

- Drilling Operation: The drill bit, guided by a flexible downhole motor and advanced measurement tools, follows the planned trajectory. As it moves through rock formations, sensors continuously monitor the angle, depth, and direction of the drill bit, enabling real-time adjustments to stay on course.

- Completion and Evaluation: Once the well has reached the desired target, it is reinforced with casing and cementing as needed. Engineers then assess the well’s productivity and integrity before beginning resource extraction or infrastructure installation.

Directional drilling often requires specialized equipment, such as rotary steerable systems (RSS) and mud motors, which enable precise directional control. Measurement-While-Drilling (MWD) and Logging-While-Drilling (LWD) tools are also used to provide real-time data, allowing engineers to make adjustments on the fly. These technologies have revolutionized the industry, making directional drilling more efficient and accurate than ever.

Applications of Directional Drilling

Directional drilling is applied in various industries beyond oil and gas, each benefiting from its precision and versatility:

- Oil and Gas Industry: Directional drilling has transformed oil and gas production, allowing for efficient resource extraction from unconventional sources like shale formations and offshore reservoirs. By drilling horizontally or at an angle, companies can reach larger resource areas from a single well, reducing costs and environmental impact.

- Geothermal Energy: In geothermal energy production, directional drilling enables access to hot rock formations deep beneath the earth’s surface. By drilling angled wells, engineers can maximize contact with geothermal heat sources, improving energy output from geothermal wells.

- Environmental and Remediation Projects: Directional drilling is used in environmental cleanup projects to treat contaminated soil and groundwater. By drilling into specific contamination zones, remediation agents can be delivered directly to the affected area, improving the effectiveness of cleanup efforts.

- Infrastructure and Utilities: For laying pipelines, fiber optic cables, and other utilities, directional boring allows installations under rivers, roads, and buildings without disturbing the surface. This has made it a popular choice in urban and sensitive environments where surface disruption must be minimized.

Benefits of Directional Drilling

Directional drilling offers multiple benefits, making it a preferred choice across industries. Here’s why:

- Enhanced Resource Recovery: By drilling horizontally or at an angle, directional drilling increases the surface area of contact with the resource, boosting productivity and recovery rates.

- Cost Efficiency: With the ability to reach wider areas from a single well or drilling site, directional drilling reduces the need for additional infrastructure, saving both setup costs and operational expenses.

- Environmental Impact Reduction: Directional drilling minimizes surface disturbance, which is crucial for projects in sensitive areas. It reduces the number of wells needed, conserving land and reducing the ecological footprint of drilling operations.

- Versatility in Accessing Hard-to-Reach Areas: Directional drilling is invaluable for reaching resources under urban landscapes, bodies of water, or protected land, where conventional vertical drilling would be impractical or impossible.

- Improved Safety: By reducing the need for multiple surface drilling sites, directional drilling lowers the environmental and human risk factors, especially in hazardous or remote areas.

Challenges and Future of Directional Drilling

While directional drilling has many advantages, it also comes with challenges. The complex nature of angled drilling paths requires specialized equipment and skilled personnel, increasing operational costs. Furthermore, geological uncertainties can make it difficult to maintain precise control over the drill bit, which can lead to higher risk in some projects.

However, advancements in automation, real-time monitoring technologies, and AI-driven predictive analytics are helping to overcome these challenges. Future developments in directional drilling technology will likely focus on further enhancing accuracy, efficiency, and environmental safety, ensuring that it remains a core technique in resource extraction and infrastructure development for years to come.

FAQs About Directional Drilling

- What is the purpose of directional drilling? Directional drilling allows for the drilling of wells at specific angles or directions, enabling engineers to reach targeted underground resources and install infrastructure with minimal surface disruption.

- How does directional drilling differ from traditional drilling? Unlike traditional vertical drilling, directional drilling follows an angled or horizontal path, allowing access to a wider area from a single entry point and enabling precise targeting of resources.

- What industries benefit from directional drilling? Directional drilling is widely used in oil and gas, geothermal energy, environmental cleanup, and construction for pipeline and utility installations.

- Is directional drilling environmentally friendly? Yes, directional drilling minimizes surface disturbance, reduces the need for multiple drilling sites, and has a smaller environmental footprint compared to traditional drilling methods.

- What tools are used in directional drilling? Key tools include rotary steerable systems (RSS), mud motors, and real-time monitoring tools like MWD and LWD, which help guide the drill along its path.

- What are some challenges associated with directional drilling? Directional drilling requires specialized equipment and expertise, and geological uncertainties can make precise control challenging. However, technology is continually advancing to mitigate these challenges.